IC Card Inlay, IC Card Inlay manufacturers,ID Card Inlay Price,ID Card Inlay manufacturers- HKCARD

Inlay is a special term for the smart card industry, which refers to a pre-laminated product that consists of multiple layers of PVC sheets containing chips and coils. Usually consists of two or three layers. There is no printing pattern on the surface. Inlay is a special term for the smart card industry. It refers to a pre-laminated product made of multiple layers of PVC sheets containing chips and coils. Usually consists of two or three layers. There is no printing pattern on the surface, and INLAY products are suitable for mass production of various types of cards in the early stage. INLAY is covered with materials with different printing patterns on top and bottom to form a colorful non-contact card by laminating again.

Structure of Inlay:

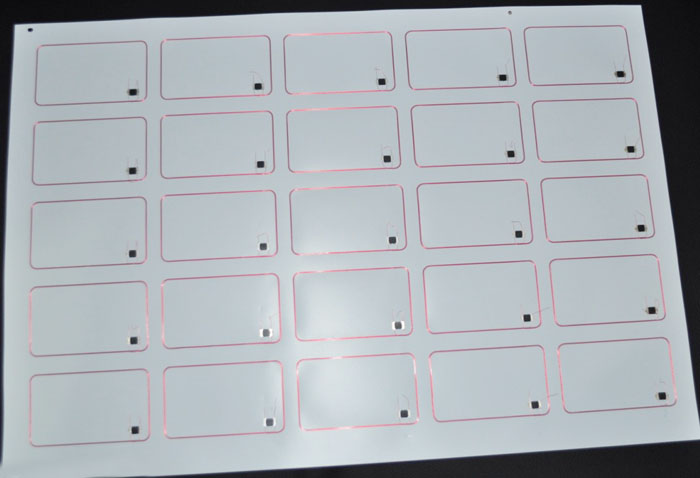

Take the three-layer structure of INLAY as an example, the upper layer is 0.1mm PVC material with rectangular holes, and the middle layer is 0.24mm PVC material with small holes, the chip is embedded in the small holes, and the coil is also Buried in this layer and connected to the chip to form a radio frequency loop. The bottom layer is 0.1mm PVC material, which plays a role in compensating the thickness. The product is suitable for the early mass production of multi-variety cards. INLAY is covered with materials with different printing patterns on top and bottom to form a colorful non-contact card by laminating again.

ID medium:

Working frequency: 125KHZ

Induction distance: 2-15 cm, the maximum reading distance can reach 1 meter

Size: ISO standard card / thick card / various special-shaped cards

Packaging material: PVC, ABS, PET

Thickness: 0.55mm thickness.

Typical applications: identification, attendance systems, access control systems, property identification, etc.

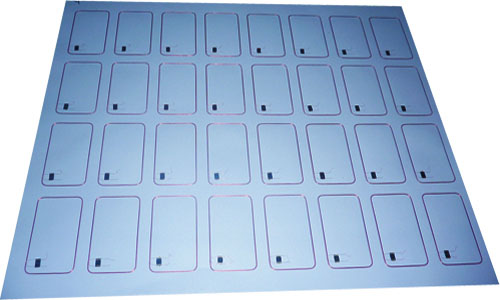

Core material specifications: 8 packs, 10 packs, 20 packs, 21 packs, 24 packs, 25 packs, 32 packs (number of core materials per large version).

ID medium material (ID core material) low frequency core material description:

The ID medium is the middle layer of the ID card containing the chip and the antenna part, also known as Inlay. This is a semi-finished product in the ID card production process. This kind of semi-finished product has already fixed the ID induction antenna and chip, and can also be pre-laminated, and then laminated into a finished card by adding an outer printed layer card base in the later stage.

The specific description is as follows:

1. Fix the general non-contact PVC into three layers: a) front printing layer; b) middle Inlay layer; c) back printing layer;

2. The front and back of the PVC card are printed with standard punching lines;

3. The Inlay layer prints the positioning line, the chip position mark and the positioning line that is synchronized with the punching line of the front printing layer;

4. Ultrasonic implant antenna, chip butt welding positioning to form Inlay;

5. Pre-laminated Inlay;

6. Three or more layers of card base laminations and laminations are laminated;

7. Punching into cards according to the printing standard punching line;

In the current card Inlay processing technology, the antenna part is processed in various ways, such as ultrasonic implanted copper wire, ordinary copper wire wound coil, printed antenna, and etching antenna. Because of the special application of non-contact cards, the performance of the cards that can be achieved by the process of implanting copper wires with ultrasonic waves is the most stable. Printed antennas and etched antennas are mostly used in electronic tags or special-shaped card applications.

Our advantage:

1. Brand: The earliest card factory. Professional card making, trustworthy!

2. Quality: More than ten years of card making experience, using the best high-quality materials and imported production equipment!

3. Service: We are anxious for the needs of customers and think about what customers think!

Order process:

First: accept orders (design draft) through QQ, WeChat, mail, express, network hard disk, etc.

Second: If the customer does not have a design draft, we can help design it.

Third: After the manuscript is confirmed, our company will be responsible for making the order, and your company will confirm (or confirm by phone).

Fourth: The production cycle is subject to the single quantity and the process.

Fifth: Delivery method: (self-pickup, express, truck, postal, railway, air,) optional.

HKCARD card factory promises: to ensure the best quality, delivery time, price and service among comparable products in the card manufacturing industry!

All HKCARD cards are encapsulated by high-density PVC material, with fine workmanship, exquisite fashion, high temperature resistance, sturdy and wear-resistant.

HKCARD ELECTRONICS CO.,LIMITED

Phone/Whatsapp/wechat:+8615817372512

Skype: byron1681

Email: byron@cardmfg.com